recarburizer

- Various specifications & stable supply

- Third-party inspection such as SGS / BV

- Customized according to your needs

- Free sample

Recarburizer, also know as carbon additive, carbon raiser. It is a product for increasing the carbon element (C).

During the steel making process, various factors may cause the carbon content in the molten steel to decrease. This will affect the quality of the finished steel. So, steel mills usually purchase carbon reductants to cope with the decline in carbon emissions.

Main application of recarburizer

- To add carbon raiser in foundry process can greatly increase the consumption of steel scrap, reduce the consumption of pig iron, or do n’t even use pig iron.

- Carbon raiser is mainly used in steelmaking. Used to increase the carbon content of steel. Carbon raiser used in high carbon steel smelting due to its high quality with few impurities.

- Carbon additive can also be used in foundries. Used to reduce impurities in pig iron, thereby reducing casting costs.

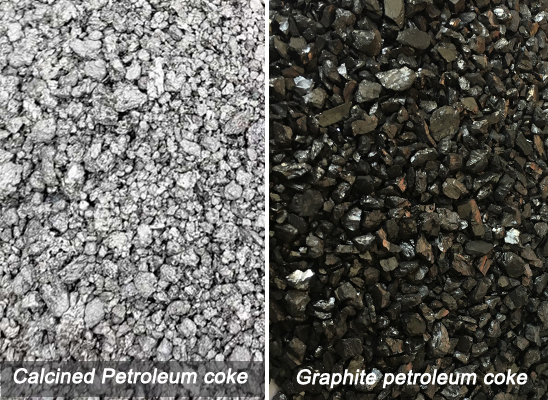

There are two commonly used carburants: calcined petroleum coke and graphite petroleum coke.

Calcined petroleum coke(CPC)

The carbon content is generally 96% -99%. The sulfur content is 0.3-0.7%. What is calcined petroleum coke used for? It is mainly used in steelmaking, cast iron, brake pads, cored wires and so on.

| Carbon Raiser | F.C% | V.M% | Ash% | S% | Moisture |

| CPC-01 | 98.5min | 0.5max | 0.3max | 0.45max | 0.3max |

| CPC-02 | 98.5min | 0.5max | 0.5max | 0.5max | 0.3max |

| CPC-03 | 98-99min | 0.5max | 1.00-0.3max | 0.5max | 0.3max |

Graphite petroleum coke(GPC)

The carbon content is 98-99.5%. The sulfur content is 0.05-0.03%. Mainly used for nodular cast iron. It is characterized by fast absorption, high carbon and low sulfur.

| Carbon Raiser | F.C% | V.M% | Ash% | S% | Moisture |

| GPC | 98-99.5min | 0.5max | 0.3max | 0.05-0.03max | 1max |

Packing and delivery of carbon additive

Size: 60-80mesh; 80-100mesh; 100-200mesh; 200-300mesh; 0-0.5mm; 0.2-4.0mm; 0.5-6.0mm; 1-3mm; 1-5mm; 1-10mm; 25-65mm; 1-100mm.

Packing:

- Small bag: 25kg kraft bag or PP bag.

- Big bag: 1000kg Jumboo bag

- According to customer's requirements.

In addition to the above two recarburizers, metallurgical coke recarburizers and calcined coal recarburizers are also available. The specifications are as follows:

| Carbon Raiser | F.C% | V.M% | Ash% | S% | Moisture |

| Metallurgical coke | 85max | 1max | 15-18 | 1 | 1max |

| Calcined anthracite | 91-95 | 1max | 4-8 | 0.4-0.6 | 1max |

Anyang Wanhua is a professional ferroalloy manufacturer. The recarburizer produced is of good quality and low price, and is loved by many customers. Contact us now!